One Team, one vision

BALLAST WATER TREATMENT SYSTEM RETROFit

BALLAST WATER TREATMENT SYSTEM RETROFIT SOLUTIONS

Hidramar Group your One-Stop Shop for BWTS Retrofit Solutions

The IMO has adopted the International Convention for the Control and Management of Ships’ Ballast Water and Sediments (BWM Convention) to regulate discharges of ballast water and reduce the risk of introducing non-native species from ships’ ballast water.

Aware of these environmental regulations, our engineering team has developed a wide range of options to help our clients to fulfill the requirements of the industry. Supported with cutting edge technologies we can deliver on the most cost-effective bases the full commissioning without delaying the operations of the assets; Delivering a turn-key solution up to our client’s demands on the allotted budget and time.

Working together with several approved systems fabricators and integrating with the Owners Technical Team, we customize the installation of the equipment according to manufacturer’s standards while taking into consideration the periodic surveys of the units and the best performance while operating.

BALLAST WATER TREATMENT SYSTEM RETROFIT SOLUTIONS

BWTS RETROFIT Basic engineering

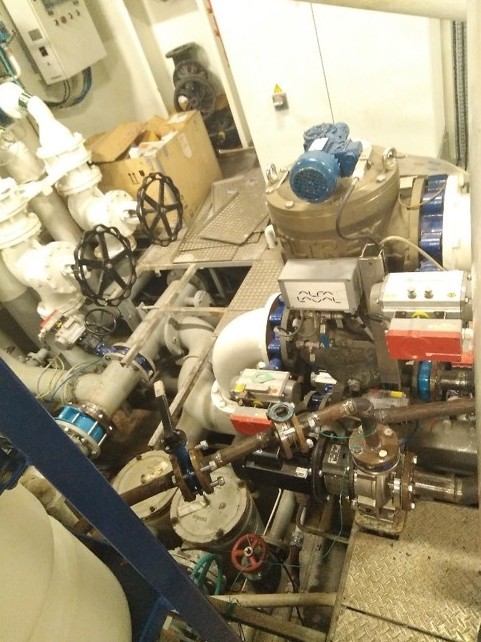

- Onboard survey and compile technical information.

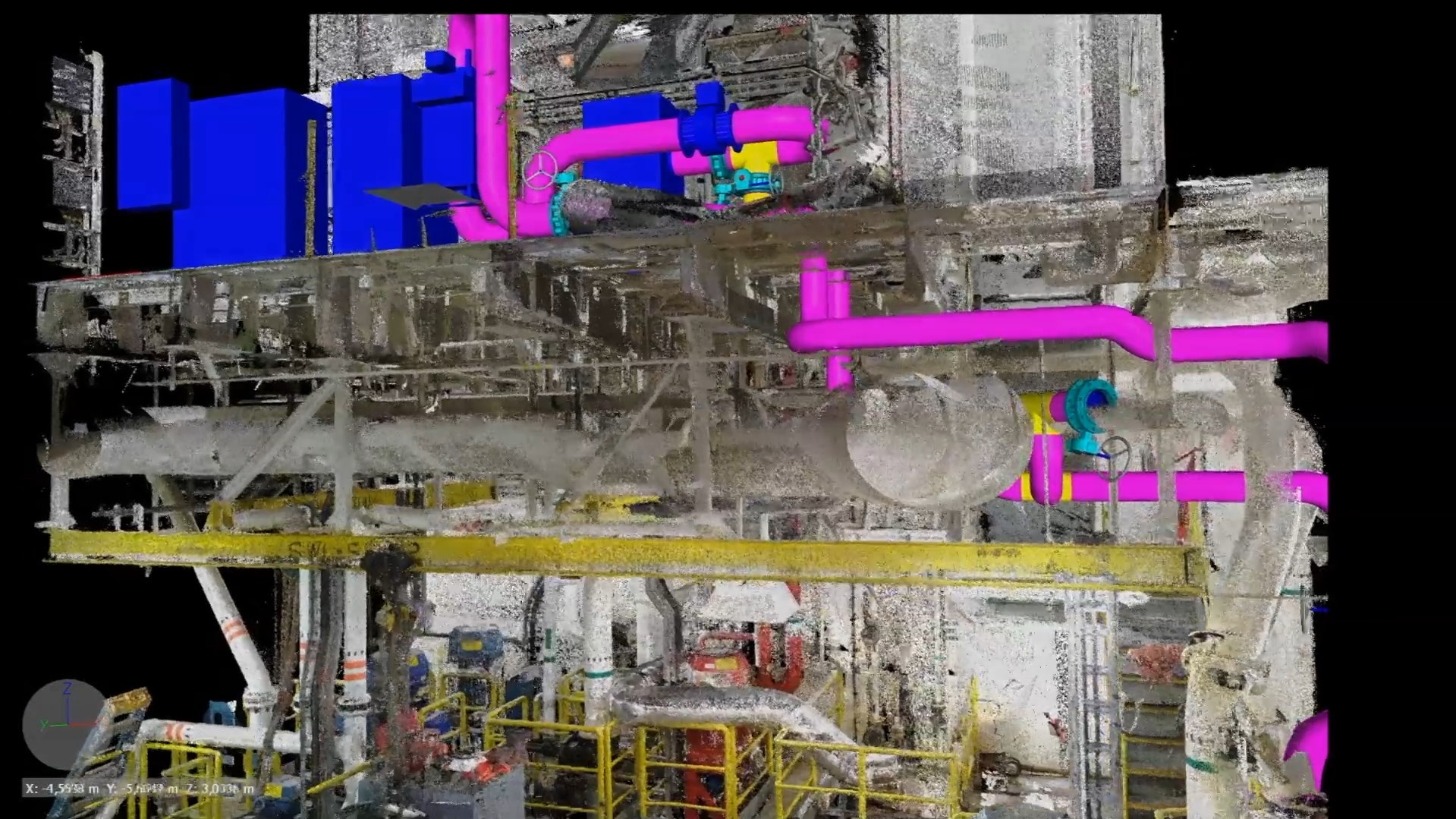

- Modeling with 3D Scanning and modeling.

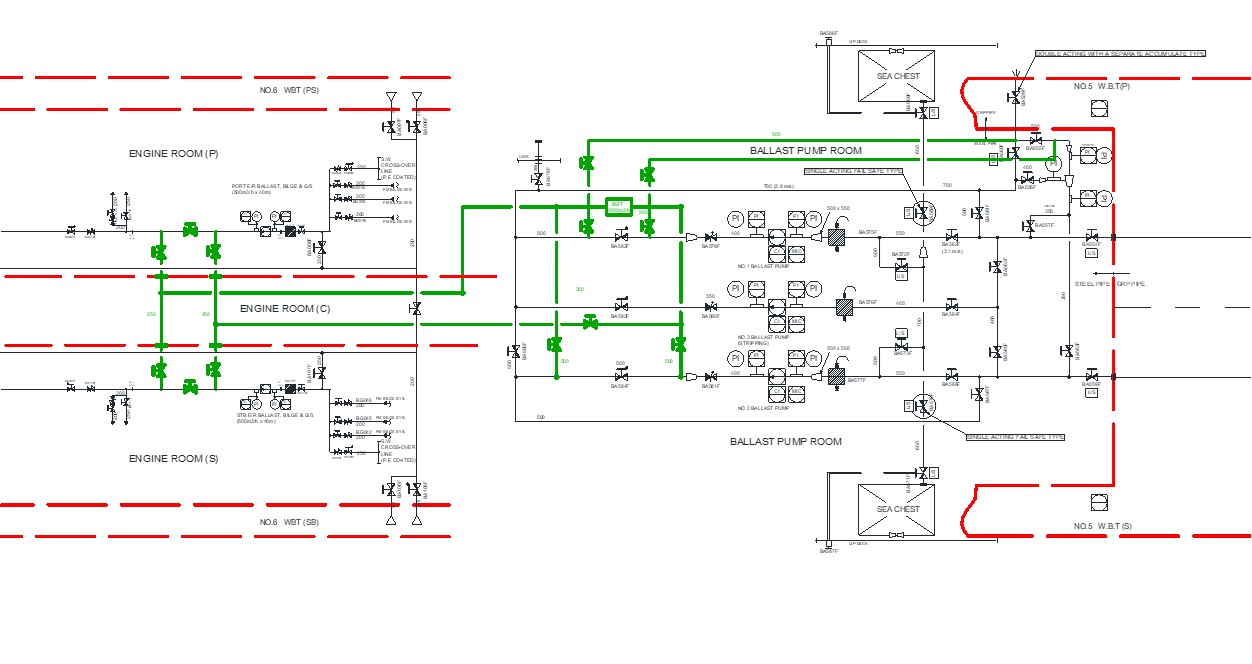

- Vessel diagrams and drawings will be schematic updated with the BWTS installation and sent to the classification society for approval.

Prefabrication of Out-fittings as per 3d modeling

- Pipe lines fabrication works on galvanized or epoxy components.

- Bulkhead penetrations and cable trays installations.

- Chemical storage Tank Fabrication if needed.

BALLAST WATER TREATMENT SYSTEM RETROFIT SOLUTIONS

Hidramar Group commercial team will be back to you ASAP.

Ballast water treatment system installation

- Preinstallation onboard, considering our strategic location we can bring onboard our riding squads crew to progress while the journey.

- Procurement and prefabrication of all the elements in order to save precious time.

- Installation once in drydock where ever it goes on.

- Support while the commissioning together with manufacturer and Certification by Class Society.

BALLAST WATER TREATMENT SYSTEM RETROFIT SOLUTIONS

WHY HIDRAMAR IS YOUR PARTNER OF CHOICE:

- Hidramar provides shipyard technical support, engineering, production, and repairs services in the Canary Islands to the Shipping and Oil & Gas industries since 1989.

- Our Shipyards are, Strategically, located in the middle of the Atlantic Ocean, in the route that connects three continents.

- Established on a free trade zone to reduce the time and cost of all the operations.

- High quality and safety standards developed on the demands of the Oil and Gas Industry.

- Inhouse workforce to execute locally & internationally through riding squads, on the most cost-effective bases.

- Hidramar Group provides retrofit solutions anywhere you need it, with our Shipyard in a box for this specific scopes.

- A fixed price for turnkey solutions.

BALLAST WATER TREATMENT SYSTEM RETROFIT SOLUTIONS

Detail Engineering

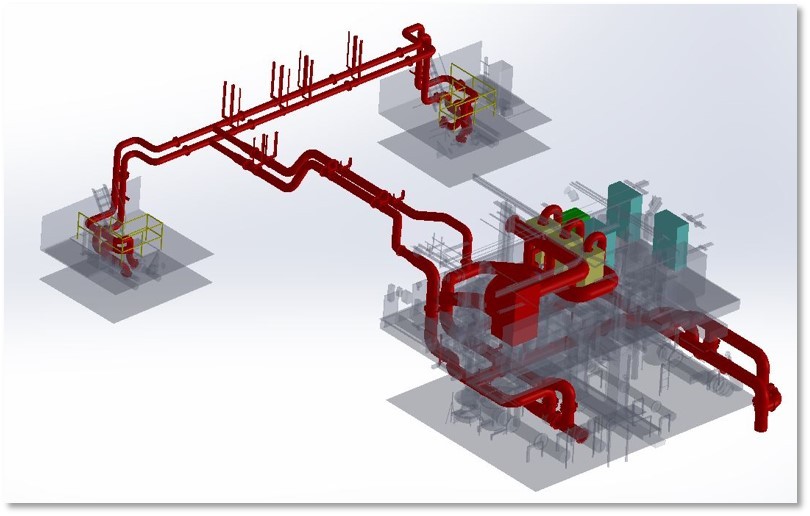

Detailed engineering produce isometric drawings for all piping and structural requirements, from 3D modeling.

Prefabrication and installation plan will be projected to reduce the downtime.

BALLAST WATER TREATMENT SYSTEM RETROFIT

Detail Engineering for Ballast Water Treatment Retrofit

Our Engineering team will do the hydraulic, electrical and structural analysis to assess if the design fit for operational purpose.

Detailed drawings and documents for prefabrication and installation are created during the detail engineering phase.

BALLAST WATER TREATMENT SYSTEM RETROFIT SOLUTIONS

Hidramar Group, your Shipyard in a Box

We like to be innovative, offering our clients a global solution to save downtime with our newest concept: the cost-effective Shipyard in a box. It is the most comprehensive answer to our clients’ needs in order to carry out the Ballast Water Treatment System retrofit during the offshore journey.