One Team, one vision

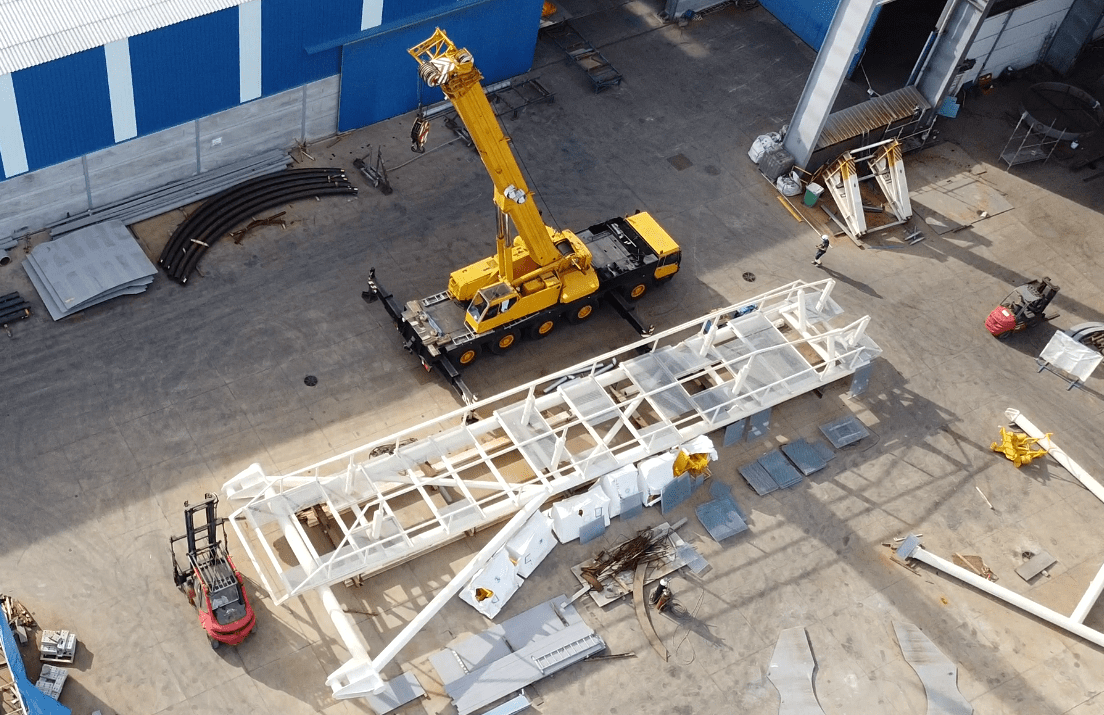

OFFSHORE STRUCTURE FABRICATION

OFFSHORE STRUCTURE FABRICATION

Our willing is to be the preferred partner of our clients and to build up a relationship of benefit to both parties.

Facilitated by the combination of our local labor supported by international expertise, by our lean manufacturing processes, by our commitment in term of quality, safety, on-time delivery, we provide cost-effectively, Engineering, Procurement, Fabrication and, Maintenance services to our clients including offshore, subsea and, renewable energy companies.

Based on our flexibility and our commitment to satisfying our clients, we can provide services in our facilities or away from our home base to be part of their success. On every single project, we develop tailor-made execution plans to satisfy these very demanding sectors.

OFFSHORE STRUCTURE FABRICATION

WE CAN DELIVER

Installation Aids

Trawling protections

CALM Buoy / Single Buoy Moorings

MORE INFO

Pig Launcher & Receiver

Mid Water Arch

WYE / TEE modules

Flare Tower / Vent Mast

Substations

Living quarters

SSIVs

Topsides’ piping

Monopiles

SDUs / UTAs

Goosenecks

Subsea rigid jumpers / spools

Risers Guard

PLETs/ PLEMs/ ILTs

Integrated Template Structures Jackets

Module fabrication and assembly

MORE INFO

OFFSHORE STRUCTURE FABRICATION

EPC Business Unit Services

Project Management

On every project, a management team is assigned to put in place all Key Performance

Indicators to define and control the project schedule, budget, quality, safety, and risks.

The project team shall continuously ensure good communication and reporting to our

clients and our management, that the changes are efficiently managed not to impact

the quality and delivery of the project. Part of the project success, the documentation

shall be efficiently managed to make sure that the client´s requirements are fulfilled and

to ensure full traceability.

Fabrication Engineering

Our engineering team is focused mainly on supporting the fabrication activities by preparing all fabrication drawings, shop drawings, nesting sheets, cutting sheets, fabrication aids design, associated calculation notes if needed, layouts, lifting and handling plans, procedures, welding engineering.

Fabrication methods engineer, welding expert are the key enablers to foster

works preparation between our Project Management, Engineering team and

our Construction team´s operational expertise.

On top of the Offshore structure fabrication support, we can provide a Design Engineering service on demand. Hidramar Group has got the capability of performing structural Finite Element Analysis with Ansys software, piping calculation, and routing, naval architecture design.

Procurement

Our Procurement team has developed a local and international

network to supply and expedite raw materials complementing what is

free-issued by the clients, consumables required for the Construction

team, services by others to complement our own services.

The continuous performance evaluation of our suppliers allows us

to supply what is required whatever the applicable standards or

specifications and within the best achievable schedule.

Construction

Our Construction team ensures the manufacturing of goods, products ordered by the clients by following applicable procedures and state-of-the-art fabrication methodologies defined upfront with the Engineering department to ensure lean manufacturing processes all the way through.

Our capabilities in terms of structural, pressure piping, blasting & painting, instrumentation, electrical works allow us to fabricate a very large range of products always with a very high level of productivity, quality, and safety.

By continuously monitoring our performance indicators related to the fabrication activities, improving our facilities and, investing in modern machines, we continuously increase our capabilities and capacities in delivering large scale fabrication services with lean manufacturing processes.

OFFSHORE STRUCTURE FABRICATION.

OFFSHORE STRUCTURE FABRICATION.

We provide cost-effective Engineering, Procurement, Offshore Structure Fabrication, and, Maintenance services.